Precision, safety, and weather all had to line up perfectly on this one.

On a cold, wet rooftop in Surrey, ECS delivered a motion-control upgrade for a university research antenna system that needed accurate, repeatable rotation. The challenge? Maintain positional precision while working safely in unpredictable outdoor conditions.

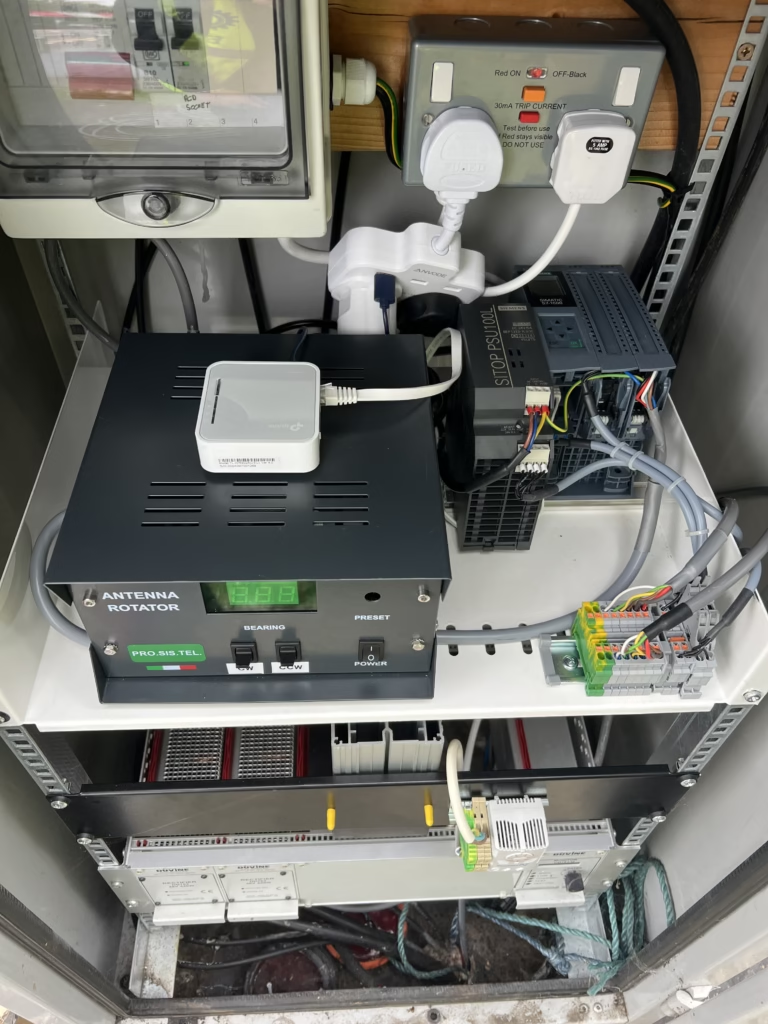

Our engineers designed and installed a Siemens-based control package with encoder feedback and software-set safety limits, giving the researchers intuitive control via a simple HMI interface.

The result, smoother operation, safer limits, and a reliable retrofit that’s ready for future upgrades like remote diagnostics through ECS Connect.

The Challenge: Precision, Safety, and Reliability

The university’s research group required a dependable way to rotate a rooftop antenna array during live experiments. Their goals were clear:

- Enable accurate, repeatable rotation to specific azimuth angles

- Provide real-time positional feedback for test reporting

- Introduce software-enforced safety limits to prevent over-travel

- Retrofit the new system into the existing pole and cabinet hardware with minimal disruption

Working at height and in exposed conditions meant the project also needed a robust installation plan that considered weather, risk, and coordination with the university’s estates team.

ECS Solution: Siemens-Based Motion Control System

ECS proposed a compact, reliable motion-control package built around the Siemens S7-1511C PLC, chosen for its flexibility and serviceability in academic research environments.

Key features of the system include:

- Encoder feedback for precise position monitoring

- Software-set safety window (approximately ±90°) to limit travel

- HMI “Go-to-Angle” interface allowing simple, intuitive control

- Safe torque limits and interlocks to protect both the equipment and users

- Built-in expandability for future Ethernet or Wi-Fi connectivity

The control panel reused the existing enclosure footprint to save time and reduce cost, while providing a clean and professional layout that simplified maintenance.

Implementation and Results

Despite a few weather-related delays, the project was completed smoothly with careful planning and updated Risk Assessment and Method Statements (RAMS). ECS worked closely with the university team to schedule installation around the forecast, ensuring safety and minimal downtime.

Performance outcomes:

- Smooth 360° motion at ~90 seconds per full rotation

- Stable operation under varying load conditions

- Simple, readable HMI screens with clear status indicators

- Full compliance with site safety documentation

After final commissioning, ECS supplied test data and operating documentation to support the project’s milestone reporting.

Future Applications and Lessons Learned

The project highlights how motion-control retrofits can extend the lifespan and capability of existing research infrastructure.

With the addition of ECS Vault, the same installation could manage secure code backups, asset documentation, and lifecycle tracking, while ECS Connect offers optional remote diagnostics if future support is required.

The solution design and HMI layout developed here are already being considered as a template for similar motion-control applications in other academic and industrial settings.

Talk to ECS About Control System Upgrades

Whether it’s antenna control, robotics, or process automation, ECS designs control systems that work reliably in the real world, rain or shine.

Our engineers combine hands-on site experience with proven technology platforms to deliver safe, efficient, and maintainable solutions.

👉 Get in touch with ECS Projects to discuss your next control system upgrade, or explore:

- ECS Connect – Remote PLC Support

- ECS Vault – Secure Digital Asset Management

Key Technologies

- Siemens S7-1511C PLC

- Encoder-feedback motion assembly

- HMI angle-control interface

- Software-set safety limits

- Existing cabinet retrofit