In the high-pressure world of manufacturing and FMCG, operational continuity is everything. Production relies on the seamless rhythm of complex machinery and skilled engineering teams. When that rhythm is disrupted, whether by downtime, demand spikes, or breakdowns, the default response is almost always the same: ask the current engineering team to work overtime.

At first glance, this feels practical. A quick fix to keep things moving. But hidden beneath the surface, overtime is silently eroding margins, adding avoidable costs, and increasing operational risk.

The Scale of the Problem

The UK’s manufacturing sector is already under strain:

- £180 billion lost annually due to unplanned downtime (The Manufacturer).

- A projected 1 million engineer shortfall by 2030 (SOE).

- Nearly 20% of the workforce retiring within the next five years (RAEng).

- 49% of businesses struggling to recruit engineers (IET).

With shortages worsening, overtime has become a systemic stopgap. But the real cost is far higher than most businesses realise.

Why Overtime Costs More Than You Think

On paper, paying an engineer extra hours might seem cheaper than hiring additional staff or contractors. But factor in statutory and employer costs, employers’ NIC (15%), pension contributions (8%), and holiday pay accrual (12.07%), and that’s 35% above the base overtime rate.

That’s before you consider hidden costs such as:

- Administrative time arranging cover

- Engineer fatigue leading to slower work or errors

- Increased safety risks

Knock-on inefficiencies in other processes

The Permanent Workforce Cost Burden

Even without overtime, permanent engineering staff represent a significant fixed cost base. Beyond salary, employers are paying for:

- Recruitment – Agency fees of 20–30% of salary are common for hard-to-fill engineering roles. With an average tenure of around two years, this cost repeats.

- Onboarding & Training – Productivity is often below 50% during ramp-up. Ongoing training costs average £5,000 per engineer annually.

- Benefits & Equipment – From health insurance to diagnostic tools, PPE, and software licences, these add up quickly.

- Admin & Compliance – Payroll, HR management, leave tracking, and regulatory compliance all consume time and money.

When modelled realistically, the total employment cost for a £55,000 engineer can be close to double their base salary.

Why Overtime Reliance Becomes a Trap

Most overtime isn’t caused by poor planning, it’s a natural consequence of operational realities:

- Planned Leave – Covering annual leave means paying other engineers extra.

- Unplanned Absence – Sickness disrupts schedules and forces reactive cover.

- Staff Turnover – Losing experienced engineers means knowledge loss and higher workloads for the remaining team.

- Demand Surges & Breakdowns – Urgent cover at premium rates becomes the only option.

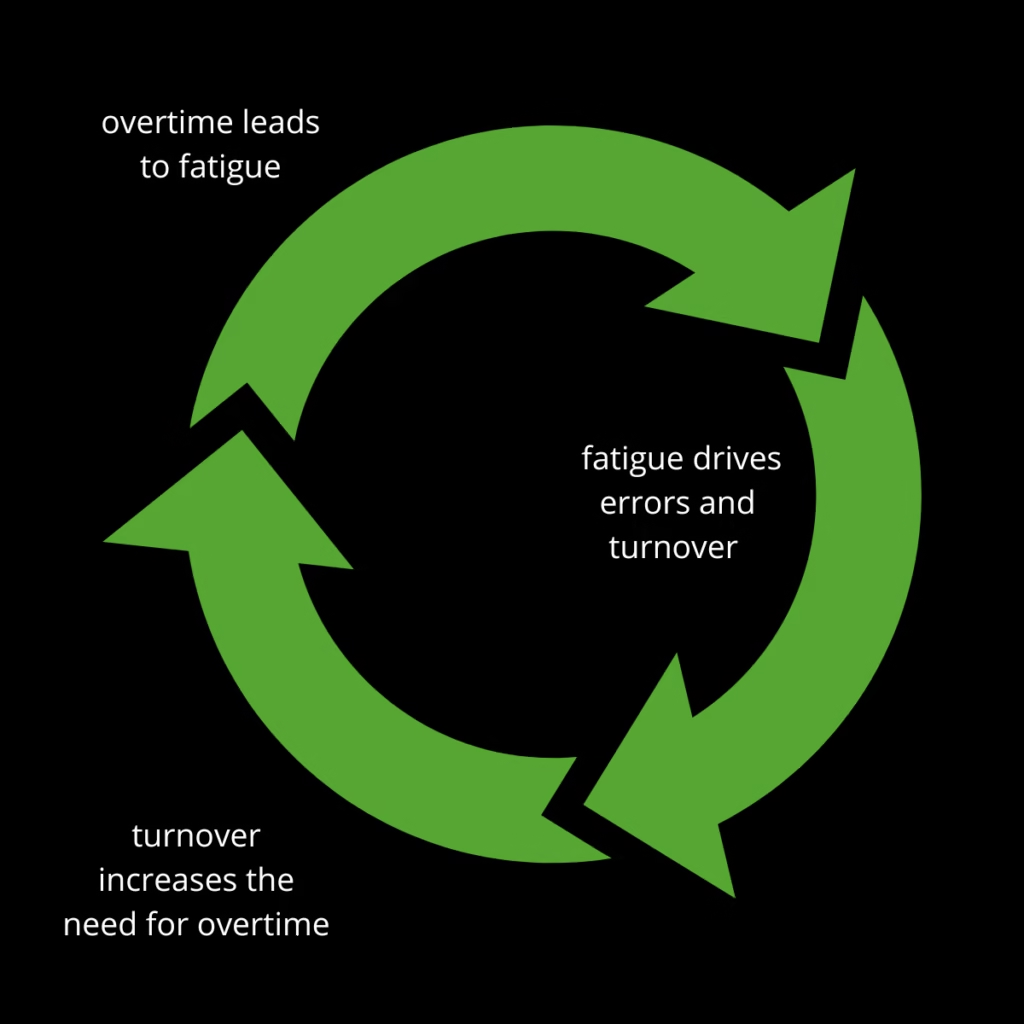

This cycle is self-perpetuating: overtime leads to fatigue → fatigue drives errors and turnover → turnover increases the need for overtime.

The Human & Compliance Risks

Overtime dependence isn’t just a cost problem, it’s a compliance and safety risk:

- Ethical Audits – Non-compliance with standards like the ETI Base Code can damage supply chain relationships.

- Burnout & Morale Drops – Extended hours lower job satisfaction and retention.

- Increased Error Rates – Fatigued engineers are more likely to make costly mistakes.

- Safety Incidents – Accident risk rises significantly with fatigue.

- Working Time Regulations – Exceeding average weekly hour limits can lead to tribunal claims and fines.

A Better Way: On-Demand Engineering Support

The solution isn’t to stretch your core team further; it’s to align your engineering resources with actual demand. That’s where ECS’s Shift Hero service comes in:

- Pay only for productive hours – No long-term salary, benefits, or recruitment overheads.

- Access the right skills instantly – From mechanical to automation engineers, fully vetted and compliant.

- Plug gaps fast – Whether it’s sickness cover, holiday cover, or surge demand, we deploy within hours.

- Reduce risk – Maintain compliance, protect your core team’s wellbeing, and avoid burnout.

Take Control of Your Engineering Costs

Overtime will always have its place for true emergencies, but using it as your default staffing strategy is like running your plant with a hidden leak in your profit line.

With a flexible, on-demand model, you can cut costs, protect your team, and maintain output without the hidden damage overtime creates.

Ready to reduce overtime costs and improve resilience?

Talk to ECS today about building a smarter, scalable engineering support model.